What is SAP PP?

The Production Planning (PP) module enables production planning based on both market demand and production capacity.

PP creates schedules for production, for procurement and for purchasing. This ensures that raw materials are available for production as required. The module records the production process with, for example, planned and actual budgets.

It records the movement of goods when raw material is converted into a semi-finished product.

This module plays an essential role in the supply chain of any manufacturer and is primarily designed for production managers or other people who deal with manufacturing and scheduling and are responsible for optimising production costs.

The SAP PP module has 3 main components :

- Industrie de transformation (SAP-PP-PI)

- Discrete Manufacturing (SAP-PP)

- Repetitive manufacturing

Processing industry

Process Industry is used for the production of products that cannot be disassembled. Here, a machine called a workcenter in SAP is usually used for the production of a single product. The PP-PI solution is mainly used in industrial processes that use the concept of batch management to differentiate between the items produced. The pharmaceutical, food and chemical industries in particular use this solution. Process manufacturing counts its products in litres, metres or grams.

Examples of Process Industry reports

These sample reports are available in the report library of the RapidViews PP module.

Subscribe to the Rapid Views Newsletter !

Stay up to date with our latest blog posts, upcoming webinars and news!

Discrete Manufacturing (SAP-PP)

Discrete manufacturing is used when a single machine is used for multiple production orders and these are planned according to production needs. The machine can be used to produce different products. The products produced can be counted in units.

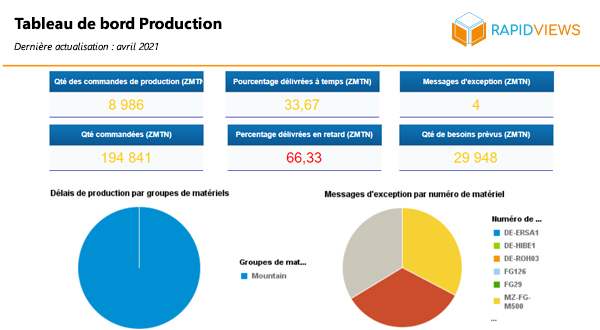

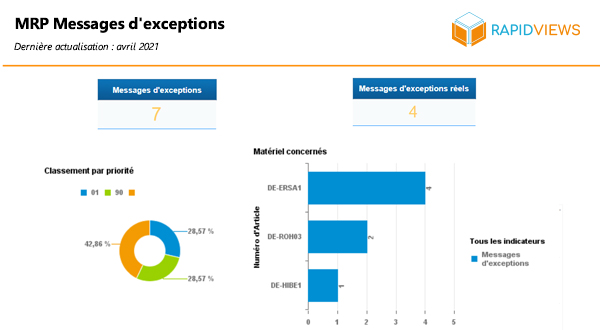

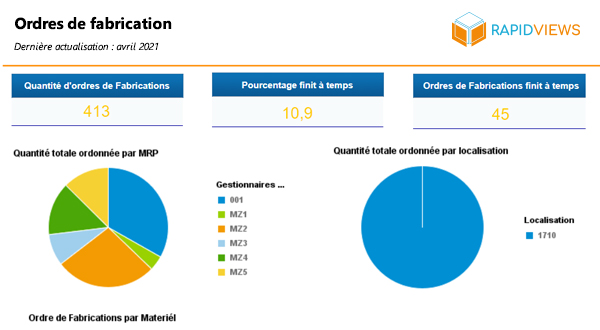

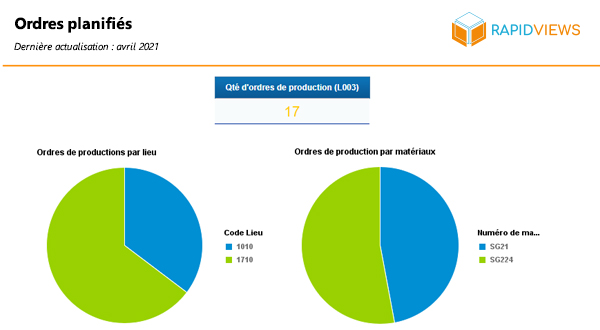

Examples of Discrete Manufacturing (SAP-PP) reports

These sample reports are available in the report library of the RapidViews PP module.

Repetitive manufacturing

Repetitive manufacturing is similar to discrete manufacturing but operates without production orders (POs). Products are produced continuously over a long period of time and production does not require much control.

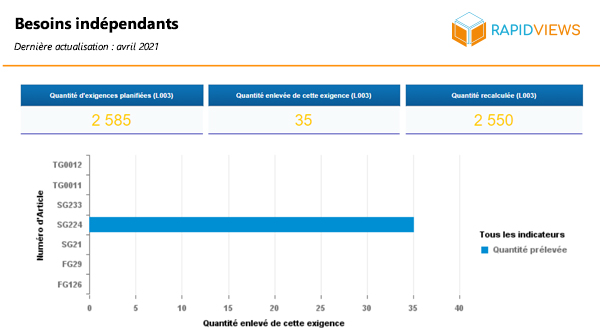

Examples of reports Repetitive Manufacturing

These sample reports are available in the report library of the RapidViews PP module.

These 3 components include concepts such as :

- Production planning

- The calculation of requirements (MRP)

- SOP (Sales and Operations Plan, sales forecast at company level)

- Industrial and commercial plan: sales forecast (at company level)

- Master production plan: production forecast (at plant level)

- Calculation of needs and resources (men and machines)

- Capacity planning

- Manufacturing control

- Production monitoring

- Costing

- Bill of material management

- Range management